Discover Specialist Lift Maintenance Services: Ideal Lift Repair Companies Near Me

Discover Specialist Lift Maintenance Services: Ideal Lift Repair Companies Near Me

Blog Article

Necessary Variables to Consider for Lift Maintenance

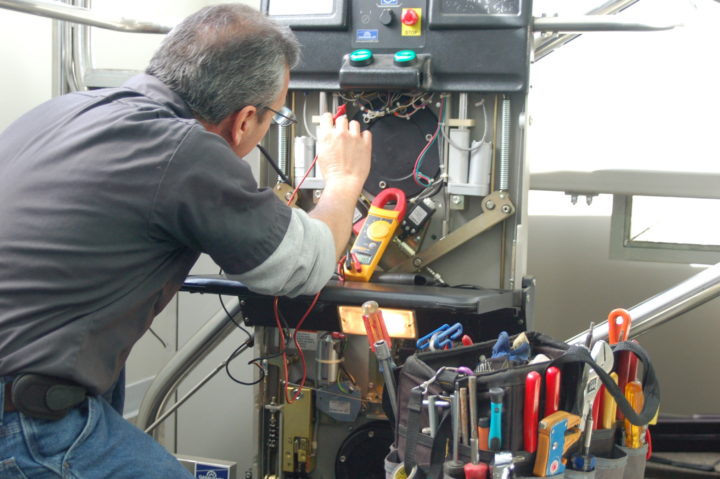

When it comes to the reliable and safe procedure of elevators, thinking about vital upkeep factors is vital. It is important for developing supervisors and upkeep workers to remain in advance of these factors to support the lift's performance requirements and conformity requirements.

Regular Examination Schedules

Conducting normal inspections not only boosts the overall efficiency of the elevator yet additionally plays a vital function in abiding by safety and security policies and industry standards. It makes sure that the elevator operates efficiently, lessening the danger of unanticipated failures that might aggravation owners or compromise security. Furthermore, regular evaluations add to prolonging the lifespan of the elevator equipment, inevitably minimizing upkeep costs and downtime.

To simplify the inspection process, many structure proprietors partner with qualified elevator upkeep companies that focus on performing comprehensive assessments and supplying prompt upkeep services. By focusing on normal inspection timetables, stakeholders can support the safety and security, integrity, and efficiency of their elevator systems.

Appropriate Lubrication Methods

Effective lubrication techniques are vital for keeping the optimum performance and durability of lift parts. Correct lubrication techniques play a vital duty in avoiding deterioration on relocating components, lowering friction, and ensuring smooth operation of the elevator system. When it concerns elevator maintenance, utilizing the ideal lubricating substances in the appropriate amounts at the suggested periods is crucial to protecting against costly repairs and reducing downtime.

To guarantee appropriate lubrication, elevator specialists should comply with producer guidelines regarding the sort of lubricating substance to be made use of for details parts such as bearings, equipments, and guide rails - lift maintenance services. Over-lubrication can attract dirt and particles, causing element malfunctions, while under-lubrication can create raised rubbing and premature wear. Routinely scheduled lubrication upkeep need to be consisted of in the overall lift upkeep plan to keep the system running successfully and securely

Keeping An Eye On Deterioration

Lift maintenance personnel ought to carry out regular examinations to recognize signs of wear on essential elements such as ropes, sheaves, overview rails, and bearings. In addition, maintaining thorough upkeep documents can assist in tracking the wear patterns of lift components over time, allowing for predictive maintenance planning. By closely keeping track of wear and tear, maintenance teams can address problems proactively before they escalate into costly repairs or unexpected downtime, ensuring the safe and efficient operation of the lift system.

Safety And Security Compliance Checks

Carrying out detailed security compliance checks is essential in ensuring the lift system fulfills all regulatory standards and functional needs. These checks additionally include confirming that the elevator's capability limitations, speed, and emergency communication systems are in line with safety and security criteria. In addition, adherence to safety and security compliance checks can prevent accidents, reduce obligation risks for structure proprietors, and prolong the life-span of the elevator system.

Emergency Situation Response Preparation

In light of the important significance of safety and security compliance checks in maintaining elevator systems, a durable emergency feedback planning method is paramount to promptly and effectively address unanticipated cases. lift maintenance services. Emergency situation feedback planning for elevators involves proactive steps Find Out More to make sure the safety of passengers and maintenance workers in the occasion of emergency situations such as power outages, entrapments, or mechanical failures

Secret parts of a reliable emergency response plan include establishing clear interaction procedures, giving normal training to staff on emergency procedures, keeping updated emergency situation contact checklists, and carrying out regular drills to exercise action activities. In addition, it is additional hints vital to have actually assigned workers accountable for collaborating emergency reactions and making sure that needed devices, such as emergency lighting and communication devices, remain in functioning order.

Final Thought

To conclude, it is vital to focus on routine evaluation schedules, correct lubrication strategies, monitoring wear and tear, safety and security conformity checks, and emergency situation action planning for elevator upkeep. By carrying out these necessary elements, building proprietors can make sure the safety and efficiency of their lifts, eventually decreasing the risk of crashes and malfunctions. Constant maintenance practices are important for lengthening the life expectancy of elevators and making certain the wellness of individuals that depend on them for transportation.

Consistently arranged lubrication maintenance must be included in the total elevator upkeep plan to maintain the system running successfully and safely.

Lift maintenance employees ought to perform routine examinations to determine indicators of wear on essential parts such as ropes, sheaves, guide rails, and bearings. In addition, keeping thorough upkeep records can aid in tracking the wear patterns of elevator parts over time, permitting for predictive upkeep preparation. By carefully monitoring wear and tear, maintenance groups can deal with problems proactively prior to they rise into expensive repairs or unforeseen downtime, making certain the safe and effective operation of the lift system.

Report this page